Table Saw Blade Height Readout

Background

As a part time woodworker

(and not a very accomplished one at that) I'm always looking for ways

to improve my accuracy and precision. Along those lines I

have added an Incra

TS III Fence to my Jet 10"

contractors saw, a Wixie

Digital Readout for blade

angles, and numerous home

made jigs

and fixtures all in my quest for

more accuracy. The Incra fence has been a great addition due

to its excellent accuracy and repeatability. What I was

missing was an accurate way to measure and set the height of a saw

blade above the table. Like most table saws the blade height

is

set with a hand crank that controls a worm gear/spur gear segment

arrangement that raises the blade by pivoting the arbor arm.

While the system works, there tends to be backlash in the

gears

that makes it difficult to set the height accurately and it's easy to

overshoot. Then you have to come down below the desired

setting

and raise the blade back up again. Although you can measure

the

height with a ruler or height gauge, you still need to make a trial cut

and then measure the cut to check for accuracy. You can

adjust

out some of the gear backlash but, if you get the gears too tight, they

will bind up. I could not find a commercial unit to

accomplish this task so I set out to design my own.

Sensor Selection

I tried various sensor approaches including linear pots,

rotary

pots, even an LVDT. I also looked at cheap digital calipers

and

some of the sites for hacking them to read the values with a

microcontroller. One of the problems is that the saw blade

arbor

pivots

on

an axis, most of these sensors read a linear distance, and the height

change is not linear with the rotary movement of the arbor. I

considered an encoder attached to the pivot point but that became a

complicated mounting problem. I finally

settled on using an accelerometer attached directly to the arbor arm.

Besides measuring acceleration as the name implies, an

accelerometer is also a very good device for measuring tilt.

After some research, I chose an Analog

Devices ADXL202e.

The guts of this accelerometer consists of a mass suspended

by

polysilicon springs that deflects when the chip is subjected to a

positive or negative acceleration. The deflection of the mass

moves a central plate between two fixed plates and changes the

capacitance of these plates. The electronics of the chip

ultimately produce a duty cycle modulated wave, the frequency of which

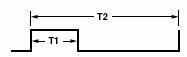

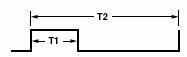

changes with acceleration. The signal looks like this:

where T2 represents the frequency of the signal and T1

represents

the amount of acceleration or deceleration or, in our case, tilt angle.

When the chip is level, the duty cycle is approximately 50%

and

then increase or decreases as the chip is tilted. By changing

a

single resistor, you can change the complete cycle frequency of the

output from 0.5 ms to 10 ms. I chose to use the longest

frequency since speed was not critical and I wanted to get

the

most

resolution that I could. So, in the figure above, T2 would be

10

ms and T1 would be proportional to the tilt angle.

Reading The Sensor

Now that I had a sensor, I had to have a way to read it and

display the results. I have been playing around with Atmel AVR

processors for a while now and so I decided to use an Atmel ATMEGA8

microcontroller. The plan is to start the internal counter in

the

processor and then count the number of counts for the T1 part of the

cycle as well as the entire T2 cycle. Then dividing the T2

counts

by the T1 counts gives us the duty cycle of the output. This

should be proportional to the saw blade height. I decided to

use

a simply 2 line by 16 character LCD

display since they are inexpensive, readily available, and

easy to interface. I also planned to use Bascom

for the programming. Bascom is a very full featured Basic

compiler for the entire AVR line of controllers.

I

used an 8.000 mhz crystal on the processor and a prescale of 8 on the

counter. With that combination, I should get one count every

microsecond and 10,000 counts during the 10 millisecond period.

In the real world I consistently read about 8350 counts.

I'm not sure what the discrepancy was - it may be processor

the

crystal, the accelerometer itself, the resistor used to select the

period, or the fact that I was using basic instead of assembly

language. The important part is that the count was very

repeatable which is what was important to me. I did find that

the

output of the accelerometer tended to vary with ambient temperature so

I added temperature compensation to improve the accuracy of the reading.

Once

I attached the accelerometer to the saw arbor and began to take

readings, I found that the saw height was in fact linearly proportional

to the blade height. This worked out great and made it very

easy

to calibrate the output.

Putting It All Together

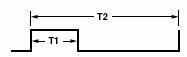

I ened up with two printed circuit boards. One has the

accelerometer, the temperature measuremnt device, and a few resistors

and capacitors. The other board has the main processor, the

display, a programming header and other support chips. Here

are

the two boards assembled and ready to go:

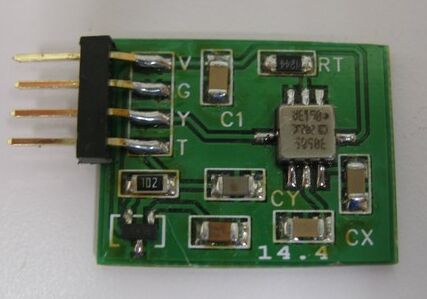

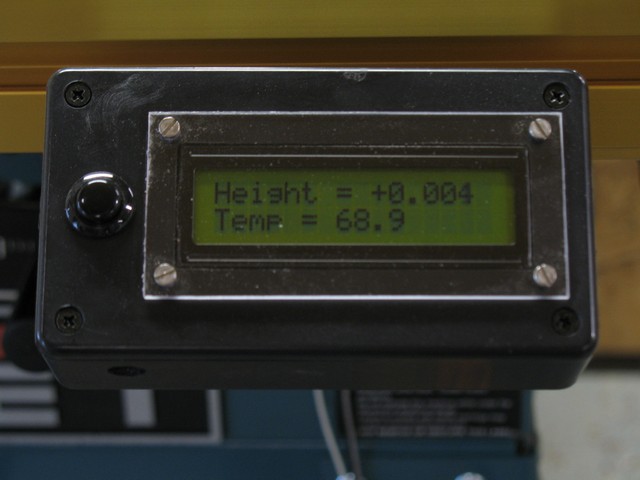

The display looks like this after being assembled:

I attached the accelerometer board to the saw arbor using hot melt

adhesive and it looks like this:

Finally the finished product looks like this:

Using the Readout

Using the new readout couldn't be easier. When you first turn

on the readout or when you change blades, simply crack the elevation

until the tip of the blade is level with the top of the table and press

and hold the button for a second. This saves the current tilt

and teperature in EEPROM and becomes the new baseline data.

Then, as you crank the elevation handle, the new height is

read out on the display. If the device is left on for 30

minutes or so, the backlight will be turned off. Pressing the

button with the backlight off will turn on the backlight but will not

reset the calibration data. Of course pressing the button

with the backlight on will reset the calibration data in EEPROM.

Turning the display on with the button pressed will display

the calibration data for 10 seconds and then revert back to the normal

display if the button has been released. If the button is

still pressed at then end of 10 seconds, debug mode will be entered in

which more base data is displayed.

Programming

As mentioned before, the programming was done with Bascom and is fairly

well documented. Basically the program consists of a main

loop that takes 50 accelerometer readings, averages them, takes 50

temperature readings, averages them, and finally computes the current

height and displays that value on the LCD. There is nothing

very special about the program and it should be fairly easy to change

or modify. There are two constants that may or may not need

to be changed. They are Tempcal and Heightcal. The

Heightcal is basically the change in % duty cycle per inch of blade

travel and is currently set to 278. This represents a

theoretical resolution of about .0036". The Tempcal value

represents how much the temperature change affects the final reading.

The current value is 10 and represents a 10% contribution for

the temperature change in 0.1 F. I haven't tried different

accelerometers so I don't know if these values work in all cases.

Final Thoughts

So am I happy with results - definitely. Is the readout

perfect - no. There is some slight variation. If I

watch the readout it varies .003" to .005" or so but if I come back in

2 or 3 days, the readout is still within the same range. I

suppose I could get better repeatability and a more stable display if I

implemented a different averaging technique but that may take longer to

stabilize and the current method is plenty good enough for me and way

better than I had before.

Software and Files

I am providing all of the files in case anyone wants to build one of

these readouts. The link below will download a zip file that

contains schematics for both boards in pdf and TinyCad

format, PC Board files in jpg and FreePCB

format, Gerber files for both boards, and

the Bascom

source and hex files for the processor. I hope you

enjoy this project as much as I have.

Version 2.0 - 5/15/13

Since my first version of this device, I

have learned a lot more about Bascom and AVR programming - specifically

in the area of interrupts. So it seemed like a good time to revisit my design and upgrade the software if possible.

I

started by making several hardware changes although none of them

required changing the PCB design. The first change was to switch

to an Atmega88 since the Atmega8 is now obsolete. I changed the accelerometer to an ADXL212 since the ADXL202

is now obsolete and the new accelerometer is less temperature

sensitive. I also changed the 1.2 Meg resistor that sets the

period of the accelerometer signal to a 1.0 Meg resistor. This

shortens the period to slightly less than 8 ms which allows us to

use a prescaler of 1 and not get a wrap around on the 16 bit timer

during one period.

From a software standpoint, the new program

sets up a pin change interrupt on the processor pin connected to the Y

axis of the accelerometer. In the interrupt routine, we determine

where we are in the period and calculate the number of timer counts

lapsed since the last interrupt. We average the values over 128

readings which gives us an update rate of about once per second.

I also round the result to .005" which seems to be fine for my

woodworking projects. The result is very stable.

Besides

the zero routine which I left the same, I also added a calibrate

routine. If you hold the button down while powering up the board,

you will go into the calibrate routine. This asks you to set the

blade to zero and press the button and then raise it to a 1" height and

press the button again. That completes the calibration and the

factor will be saved to EEPROM and the program returns to normal

operation.

The new Bascom program is included in the download file above.

Questions

or Comments

Home