I have added several cameras to my home control system and

plan to

add more in the future. I also added an ASELPRO

Video Switcher

from National

Control Devices.

This is a 16X2 switcher so it

gives me plenty of room for expansion. While the cameras are

nice, what I really wanted was the ability to pan and tilt selected

cameras to change the view if necessary. I did quite a bit of

searching and most of the pan and tilt mounts were more than I was

willing to pay. I also considered building my own but, while

doable, was more packaging than I wanted to mess with. I

finally

settled on the Ninja

Pan and Tilt Camera Mounts from X-10. These

are relatively inexpensive - I got my last one on eBay

for $30 - and

appear to be reasonably well built.

The negative to these mounts, at least for me, is that they

are

controlled by an RF remote and the knock on them is that they have a

pretty limited range. My cameras tend to be spread out and I

wanted to control them from my home control system located in the

basement so that didn't seem to be a very attractive option.

There are quite a few sites around the internet devoted to hacking

these devices but most of them seem to be aimed at increasing the range

of the remotes. There's even a few where someone has replaced

the

processor in the Ninja with their own processor and custom

code.

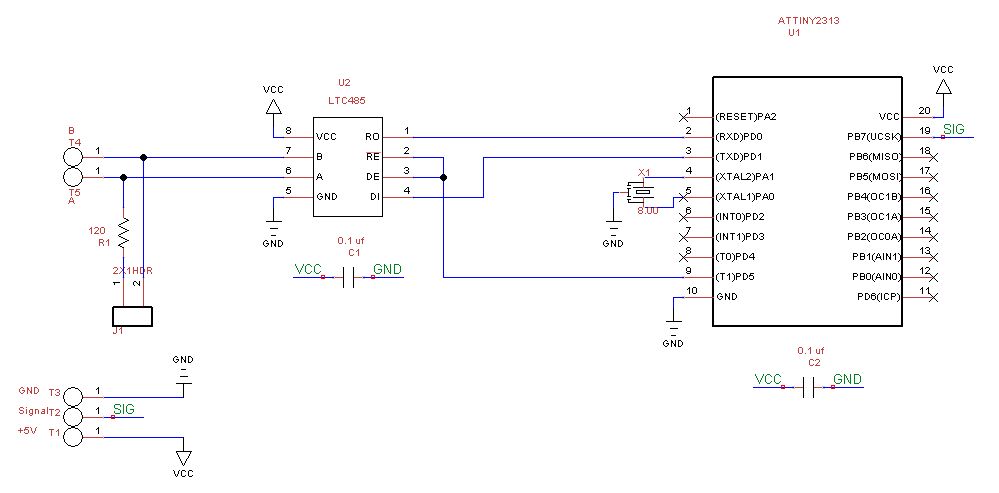

Since my cameras are all hard-wired, I decided to go with a hard-wired

approach for the Ninja as well and convert them to operate an an RS-485

network. That's what this page is all about.

As I mentioned previously, there is quite a bit of information

available on the web and the most important piece of information I

needed was the protocol currently used by the Ninja. I found

the

best descriptions on Ed

Cheungs comprehensive home automation site (although the data

was

actually provided by Dennis Hawkins) and Dave Houston's

excellent

web site. I also found all of the details of how

the Ninja

hardware worked on this site. This last modification

consisted of

replacing the micrcontroller with an SX controller and changed the

Ninja to be controlled over a serial link to a PC. It also

involved a new protocol and several new capabilities. While I

liked this approach, I wanted to control several Ninjas and the

distance would just be too great for an RS-232 connection. So

let's get started.

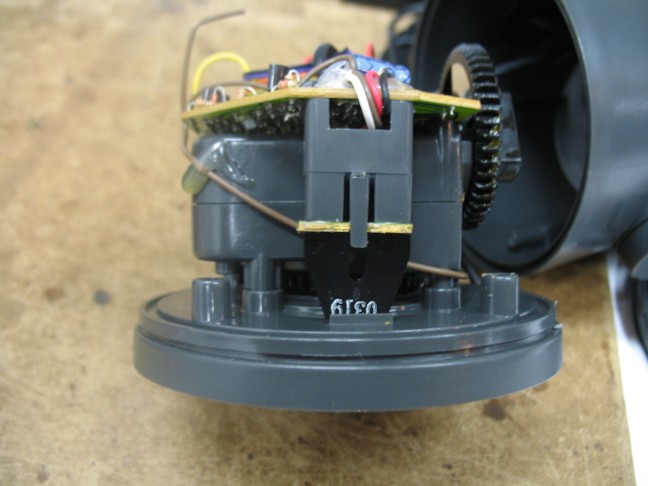

Here are a couple of shots of an unmodified Ninja disassembled

to

see the guts:

|

|

In the shot on the left you can see the PCB, main processor,

the 5

volt regulator under the mess of wiring, and the ribbon cables which

supply the power signals to the servos located under the PCB.

In

the shot on the right you can see the RF receiver board which is

responsible for receiving the RF signal and transmitting it to the main

processor. This board has 3 wires connecting it to the main

board

- the white and black wires which are +5V and Ground as well as the

yellow wire which is the signal to the main processor. Since

we

are not using RF, we will remove this board and then design our new

interface to fit in the same location using the same wires.

If we

do this correctly, the processor will never know the difference.

Before removing the board completely, I cut the wire to get a

better

look at the signal going to the Ninja processor. In order to

see

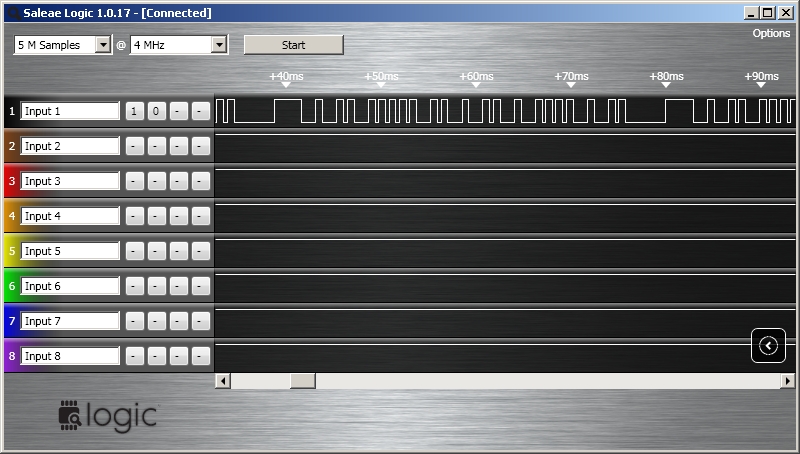

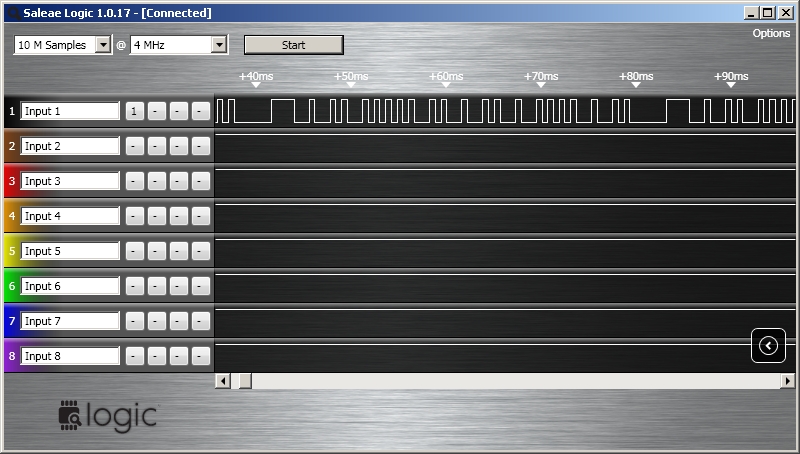

this, I used my Logic

Analyzer

from Saleae LLC. This is a great

product at a great price and, if you've never used one before, it's a

great tool for understanding whats going on with your circuits and

programming. So when I hooked up the analyzer to the yellow

signal wires, here's what I got:

If you look at the detailed

protocol

documents, you'll see that this matches the described protocol

extremely closely. Now I knew what I had to produce.

|

|

The board fit perfectly and here's the Ninja with the new

board

installed:

|

|

The only problem I had was that there was no room left on the board for a programming header which I try to put on all of my AVR boards. Since this was also my first surface mount AVR, I couldn't use a piggy-back type board in a socket to do my programming like I have done in the past. The solution was a Pomona SOIC Clip. I had a little problem getting this to work in the beginning but only because excess flux from the my soldering was causing contact problems. Here's what the clip look like in actual use:

So now I had my hardware modifications made. Before I go on

to

the software, a few more explanations are in order. The Ninja

is

powered by a 12 volt, 200 ma, X-10 controlled plug-in supply.

Although rated at 12 volts, the supplies are poorly regulated and the

ones I checked actually measured around 22 volts.

The power

supply has 3 wires going to the Ninja. Two wires provide the

operating voltage and are

active all of

the time. The third wire carries power only when

the X-10

address of the power supply is on. This tells the Ninja that

it

is being addressed and to respond to move commands. As far as

I

can tell, although there are separate commands for each home address

(A, B, C,...), the Ninja will respond to any of them if its signal lead

is powered.

Doand the Sendcmd subroutine looks like this:

'wait for address

Do

Do

Ch = Ischarwaiting()

Loop Until Ch = 1

Get #1 , K

K = K - 48 'convert from ASCII "0"-"9" to 0-9

Loop Until K = Myaddr

'now wait for command

Do

Ch = Ischarwaiting()

Loop Until Ch = 1

Get #1 , K

Cmd = Chr(k)

'this must be for us so see if it matches one of the possible commands

'and set up values for A and B for that command before calling subroutine

'to send command

A = &H0000

Select Case Cmd

Case "l" : A = &H9560 'left

Case "r" : A = &H9661 'right

Case "c" : A = &HA16C 'center

Case "u" : A = &H9762 'up

Case "d" : A = &H9863 'down

Case Else

End Select

B = &H0006 'always

If A <> 0 Then 'we have a valid command

For K = 1 To Rpt

Gosub Sendcmd

Waitms 10

Next Rpt

End If

Loop

'**********Ninja command protocol**********

'The start sequence is a 2.4ms pulse followed by a 1.6ms space. A 1-bit is a

'0.6ms pulse followed by a 1.6ms space and a 0-bit is a 0.6 ms pulse followed

'by a 0.6ms space. Only 20 bits of data are sent. A 0-bit marks the end of

'the frame. Repeats follow with no gap.

'See: http://davehouston.net/cr14a-rf.htm

Sendcmd:

Reset Signal

Waitus 2400

Set Signal

Waitus 2400

Reset Signal

Waitus 1600

For I = 15 To 0 Step -1

Set Signal

Waitus 600

Reset Signal

If A.i = 1 Then

Waitus 1600

Else

Waitus 600

End If

Next I

For I = 3 To 0 Step -1

Set Signal

Waitus 600

Reset Signal

If B.i = 1 Then

Waitus 1600

Else

Waitus 600

End If

Next I

Set Signal

Waitus 600

Reset Signal

Return

End