Digital Planer/Sander Gauge

Background

As part of my woodworking hobby, I had acquired both a Dewalt

DW733

portable thickness planer and a Performax

(now Jet) 16/32 drum

sander over the years. Both tools are fine but I have always

wished for better, more accurate thickness control. I use a

set

of calipers to measure board thickness after a pass but the actual

measurement

scale supplied on each tool is just a moving pointer on a fixed scale

so it can

be difficult

to get consistent, repeatable results. Wixey

makes a digital gauge that I

could purchase and install but what fun would that be.

Besides I

wanted a gauge that I could program to work the way I wanted it to not

the way someone else wanted it to. It would be ideal to

basically

attach the calipers I was using directly to the machine. I

had

seen numerous sites

over

the years that covered hacking and interfacing an inexpensive digital

caliper and thought that this might be a good way to go.

I use

several different sleds and jigs on both machines so a gauge which I

calibrate once and then don't have to calibrate again wouldn't quite

meet my needs. Wixey has a relative mode where you can

measure

your board, subtract the desired thickness from the measured thickness,

set the gauge to zero and then adjust the machine to remove the

required amount. My plan was to measure a board, set the

gauge to

the measured reading, and then, as you adjust the machine, the readout

will read the actual board thickness.

Hardware

As I mentioned above, my plan was to use an inexpensive

digital caliper like the kind they sell at Harbor

Freight.

The calipers are made in normally China and you can buy them

numerous

places. There are also numerous web sites which have detailed

information about hacking these calipers. I have actually

seen

them on sale at Harbor Freight for as little as $10. Here's

what mine

looked like:

The interesting thing about these calipers is that they have a

small,

sliding window that, when opened, exposes 4 connectors on the circuit

board that provide an interface to the caliper and its readings.

The interface looks like this:

The

4 connections are ground, data, clock, and 1.5 Volts from left to

right. The data is clocked out on the data pin about every

300 to

330 ms and is composed of 2 - 24 bit numbers that represent an absolute

position and a relative position since the last time the caliper was

set to zero. The numbers are in 1/20480ths of an inch.

There are a number of web sites that probably explain the

protocol much better than I could and I provide a link to many of those

sites at the bottom of this page.

I also needed a cable to connect to the caliper and Little

Machine Shop

sells just such a cable. The problem is that there really

doesn't

seem to be a mechanical standard for the caliper housing and they are

not all the same. I have three of these calipers and the

cable

only worked really well on one of them. My solution, which I

also

found on the Internet, was to solder the wires directly to

the

circuit board and provide a simple strain relief. The idea

and

detailed instructions for this modification are provided on this web

site

(which is in German but translated here into English) and worked really

well. This is what my circuit board looked like with wires

attached ready to re-assemble:

Finally

I made several modifications to the calipers themselves just to

simplify

mounting for my application. I added 2 - 1/4" X 3/16"

bushings and planned to mount them on my machine with a pair of 3/16"

shoulder screws.

Unfortunately I ignored the fact that the calipers are positive

ground (in that the +1.5 volts is connected to the frame of the

calipers). For that reason they needed to be isolated from the

metal frame of the machine so I ended up mounting the calipers with

nylon hardware. This would be optional and may not be necessary

at all

depending on your application.

Here's my completed calipers ready to go:

The

final piece of the system is the interface itself. I chose to

use

an Atmel AVR micro to interface with the calipers - specifically an

ATMEGA168. Most of the information I found on the Internet

related

to using PIC processors so this is the first AVR implementation that

I'm aware of. The program only uses 19% of the processor

memory

so a

smaller processor would work but I wanted room to grow and I only stock

2 or 3 different processors since the cost difference for a one-off

application is nominal. Here's the schematic for the

interface,

you can click on it for a larger view and the files are available for

download at the bottom of this page:

There

are several interesting things to discuss here. As I

mentioned,

the processor is an ATMEGA168

running at 8 Mhz. I probably could

have gotten by using the internal oscillator but I chose to add an

external resonator. Although I'm not currently using it, I

added

a header for RS232 serial communications in case I needed it in the

future and the internal oscillator is not always accurate enough for

reliable RS232 comms. I'm using an external 5

volt

regulated wall wart

so no need for a 5 volt regulator but I do like to provide reverse

voltage protection to my projects and that presents a minor problem

since the normal method is a

blocking diode but that would lower the 5 volts to only about 4.4

volts.

The solution was to use a PMOSFET

in an unusual configuration. Rather than a detailed

explanation, here

and here

are two sites where I got the idea and that explain this use much

better than I could.

The calipers require 1.5 volts so I used a TI TSP769 series LDO

regulator. This regulator also has shutdown capability.

I have connected this pin to a processor output pin but am

not currently using this feature. The problem with 1.5 volts

on the

caliper volts is that signals from the clock and data pins are also 1.5

volts and, since I'm running the processor at 5 volts, the Mega168 data

sheet specifys the input port high voltage needs to be a minimum of

0.6Vcc - that means I need a minimum of 3.0 volts to recognize a high

signal. I solved this problem by using a 2N3904 NPN

transistors with appropriate resistors on both the data and clock

signals.

This has the effect of boosting the high voltage to 5 volts

and also inverting both signals. This doesn't really bother

me since I can compensate for the inversion in software if necessary.

You can also see an NLAS4501

analog switch that can connect 1.5 volts to the clock pin through a 10K

resistor. This can be used in software to zero the calipers.

There is also quadrature encoder with push button switch

which provides the user interface to the caliper gauge. This

is connected according to the encoder

data sheet.

Finally there's a Crystalfontz

LCD to display the readings and three LEDs - one for power

on, one for mode display, and the final one is a heartbeat signal that

is toggled every time a new reading is received.

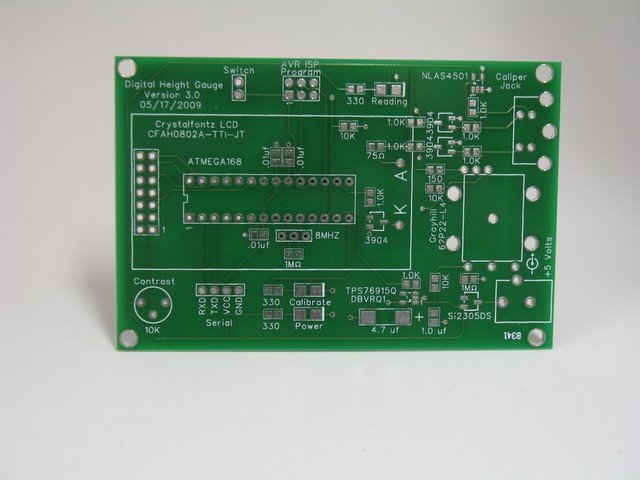

Once the schematic was designed and tested, the next thing was a PCB to

build the interface. Here's the designed and the completed

PCB:

I designed the board using FreePCB

and purchased the board through

BatchPCB.

I have used both of these for several projects now

and have been very pleased with the results. I also used an

enclosure

from SparkFun. I have used these enclosures before

and I like the size and the fact that they are clear and you can see

your project and any LEDs you might have. Here's the

populated board and the finished enclosure:

Finally, here are all of the pieces together:

Software

The software is written with Bascom

AVR from MCS Electric.

I

have been using this software for quite a few years and find it to be

very good, very fast, and easy to use. There are two

modes

in the program - calibrate

mode and measure mode. The main loop in the program checks

the

encoder

pushbutton and, when pressed, toggles between the two modes.

In calibrate mode the software monitors the encoder movement

and allows the user to dial in a measurement which then becomes the

current measurement and all further movement of the calipers are

relative to this value. In measure mode the calipers are read

with each update and this value is added or subtracted from the

calibrate value and displayed on the screen. The current mode

is displayed on the LCD as well as either the set point or measured

value. The current mode is also indicated by an LED on the

board. Both modes are controlled by interrupts.

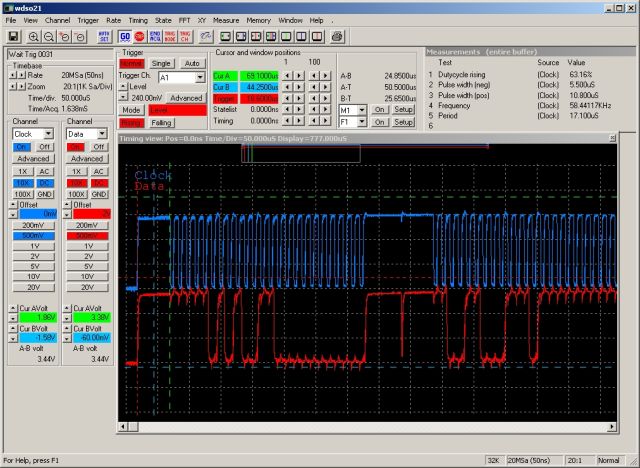

In measure mode, the clock pin is connected to the Int0 pin.

An actual set of readings only takes about a millisecond so

the software looks for any clock signal then waits 5 milliseconds to

make sure we are past a reading before enabling the interrupt, this

prevents us from starting in the middle of a reading.

Once enabled, the interrupt signals when the clock start

signal is detected and the interrupt routine clocks in the 2 - 24 bit

signals that the caliper sends out using the Shiftin routine.

Each time a new reading is available, the main loop combines

this new reading with the calibrate set point and displays this

combined

reading on the LCD. Here's what a typical reading looks like

on my scope:

The calibrate routine uses several interrupts. The two

quadrature outputs are connected to inputs which are configured as pin

change

interrupts and a separate Timer1 interrupt is also enabled.

The Timer1 interrupt occurs every 65.5 ms and increments a

variable to a max of 5. Each time an encoder interrupt

occurs, the interrupt routine determines the direction of the encoder

and checks the value of the timer variable and, using these two pieces

of information, determines whether to add or subtract to the calibrate

value and how much to add or subtract. Each time the value

changes, the reading is updated on the LCD. Using this

method, if you turn the encoder fast, the value will be increased by

large amounts and, if you turn slowly, the value will be incremented by

a minimum amount. This way you can get to a large number

quickly and then slow down to dial in the exact value desired.

Finished Project

Here are a few pictures of the finished project mounted and in

operation:

Downloads and Future Plans

I'm providing a full download package that includes all of the relevant

files for this project including:

- Schematic in TinyCAD format as well as a PDF file of the

schematic

- PCB file in FreePCB format as well as a full set of Gerber

files

- Parts list in Excel format

- Bascom AVR source file and program HEX file

You can also purchase a PCB directly from BatchPCB.

My next step is make a second gauge and install it on the sander.

In retrospect there is one thing I would probably change if I

started over again. I would probably add a large capacitor

that would keep the voltage up for a few seconds after I powered the

unit down. That way I could detect that the power was shut

off and save the current reading to EEPROM so that I could

make that the calibrate reading the next time power was turned on.

I can accomplish the same thing on this board by installing a

momentary contact switch and saving the reading if I press the switch.

I actually added a two pin header on the current PCB just in

case I wanted to do something like this.

Here are some of the Internet links that I found useful in developing

this project presented in no particular order:

Updated 3/25/10

After a few months of using the new gauge, I decided I needed to make a

few upgrades. I still had a header on the PCB labeled Switch that

I had originally thought of using to change modes until I decided to

use an encoder that had a switch built in. I left the switch

header in case I came up with another use for it. Well I

installed a small NO pushbutton switch and wired it to this header and

programmed the switch to save the current reading to the EEPROM memory

when it was pressed. Then I read that reading from EEPROM each

time the gauge is powered up. Unless I move the planer head when

the power is off to the gauge, the calibration shouldn't change between

uses of the planer.

The second change was to retain the current reading when going into

calibrate mode. Previously the calibrate offset always went to

zero. I realized that more often than not I only needed to make a

minor tweak to the setting and going back to zero each time was a waste

of time. So far I'm happy with the new changes.

This what the gauge looks like now. You can see the pushbutton in

the upper right corner.

I have included the new Bascom source and hex files in the download

package.

Updated 4/13/10

Well, this is embarrassing. I posted the update below after

mounting my new gauge and running the head up and down to make sure it

worked - but never actually running the sander. I ran the sander

today and found a major problem. Running the drum itself caused

no problems but, running the conveyor, produced major electrical noise

that caused the gauge to go crazy. The conveyor motor is a 90V DC

motor and utilizes a KB Electronics OEM DC drive.

I tried a shielded cable from the calipers to my controller but

that didn't seem to help at all. So far I have not been able to

solve this problem but am working on it. Any thoughts or

advice would certainly be appreciated. Thanks.

Well I finally got around to building and installing one of these

gauges for my Performax 16/32 Sander. The installation went just

fine and I like this even better than having a gauge on my

planer. The adjustment on the sander is very smooth and I can

dial in just the thickness I want. I did make an interesting

discovery though. The handle on my sander indicates that a

quarter turn is equal to 1/64" so a full turn would be 1/16" or

.0625". So I assumed that the screw was a 16 pitch thread.

In actuality it appears that one full turn is .0551"-.0552" which would

make it a 1.4mm pitch thread. Not a big deal but still

interesting.

So here's the readout mounted:

And here's the caliper mounted:

Thanks for reading and be sure to email me

if

you have any

questions or comments

Home