Current Sensor

Background

For a while now I have wanted some type of current sensor for

use

with my Homevision home control system. Originally I wanted a

device to indicate when a television was on since most remote controls

just toggle the power on a TV and don't know if the TV is off or on.

I tried several video sensors but I couldn't get any

of

them to operate reliably. I sort of lost track of the effort

until recently when I need some way to track the hours on my air

compressor to know when it was time for service and on my furnace to know

when it was time to change filters.

So I decided to design a current

sensor which would be simple, reliable and easy to interface to my

Homevision controller. Before I go any further I have to say

that, although I have quite a bit of experience with industrial

electrics, I am not an electrical engineer. All of my

knowledge

in this area is self taught. So I'm not guaranteeing anything

and, if you decide to build any of these, you do so at your own risk.

All I can say is that they work great for me.

Design

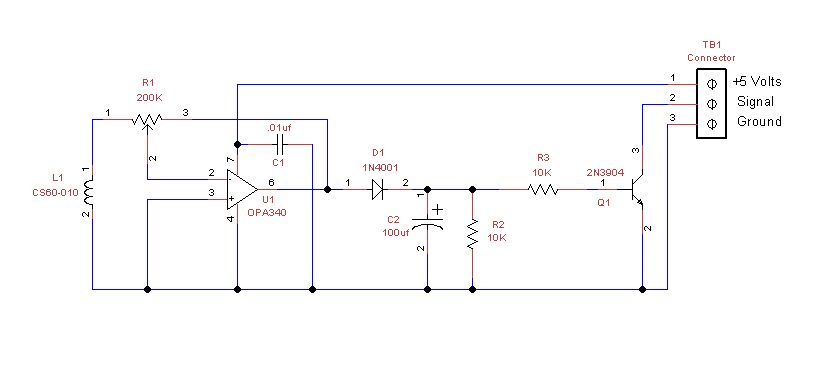

The design uses a Coilcraft CS60-101 current trransformer

which

basically converts the current in a wire passing through the center of

the coil into a voltage. Although this voltage is quite

small, it

can be amplified and then rectified to get to a useable voltage level -

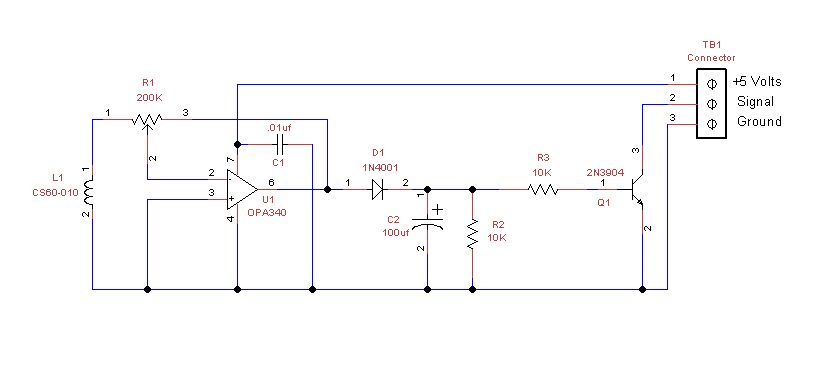

and that's just what I've done. Here's the circuit diagram:

The voltage created by the coil in the above drawing is amplified

through the OPA340 op amp based on the ratio of R2/R1. In the

drawing, R2 is the resistance between terminals 2 and 3 of the 200K pot

and R1 is the resistance between terminals 1 and 2. By

adjusting

the pot the gain can be adjusted over a wide range. The

output

voltage from the amp is half wave rectified by diode D1 and smoothed

out by the 100uf capacitor. Resistor R2 pulls the base

of transistor Q1 to ground preventing it from conducting.

When the voltage at the base of Q1 exceeds approximately 0.6

volts, the transistor will conduct and the signal from the controller,

which is normally pulled up to 5 volts, will be pulled to ground and we

get a change on the controller input signal which is connected to

terminal 2 of TB1.

Results

So far I have been very pleased with the results. I can

easily

adjust the potentiometer to the point where there is no change on the

input port until the device is turned on and then the input port

changes from 1 to 0 signalling the controller to take an action.

I have successfully used this sensor on loads from

approximately

300 ma to as high as 15 amps. Although the coil is only rated

to

10 amps, using it on loads up to 15 amps caused no problems.

The

other nice thing is that the load on the controller is only about 1 ma

- easily within its range to provide power.

Here's a few pictures of the sensor.

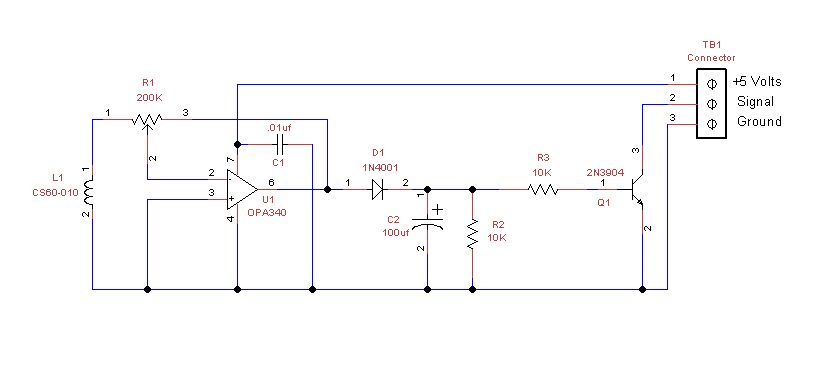

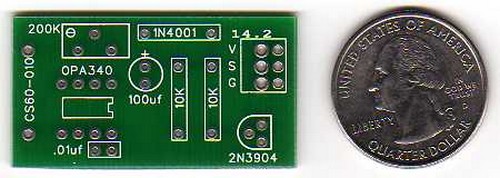

First the bare board:

Board fully populated:

Board with sensor:

Board installed:

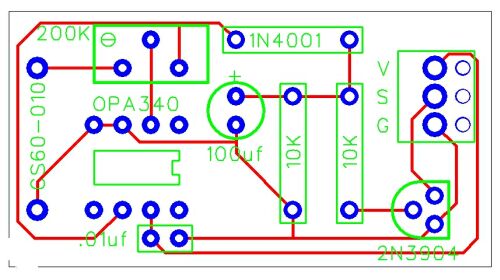

Finally PCB layout:

I also have links to images of my air compressor runtime tracking page and my furnace fan runtime tracking page.

I am also providing all of the files in case anyone wants to build one

of

these sensors. The link below will download a zip file that

contains a schematic for the board in jpg and TinyCad

format, a PC Board file in jpg and FreePCB

format, and Gerber files for the board. I hope you

enjoy this project as much as I have.

Questions

or Comments